ST Solutions identified our client’s pain point of long cycle times and broken tools, then offered a solution for process improvement. We observed the way the products were manufactured and came up with a solution that achieved the goals of shorter cycle times and reduced costs. Within 3 months of implementation, the client achieved its production goals and reduced costs by nearly $300,000 annually.

Our long-term client, a first-tier automotive manufacturer, was not able to meet production goals because tools were constantly breaking and underperforming. It took 6 separate tools to complete the necessary roughing and finishing tasks for proper machining, creating long cycle times and excess cost. The client first approached the machine dealer to ask for support, but they were unable to offer a solution. Despite having a goal of under a minute, cycle times were roughly 3 minutes.

Accuracy in parts was also critical. In order for the client to meet their corporate productivity goals, 90% of parts produced had to be exact to design.

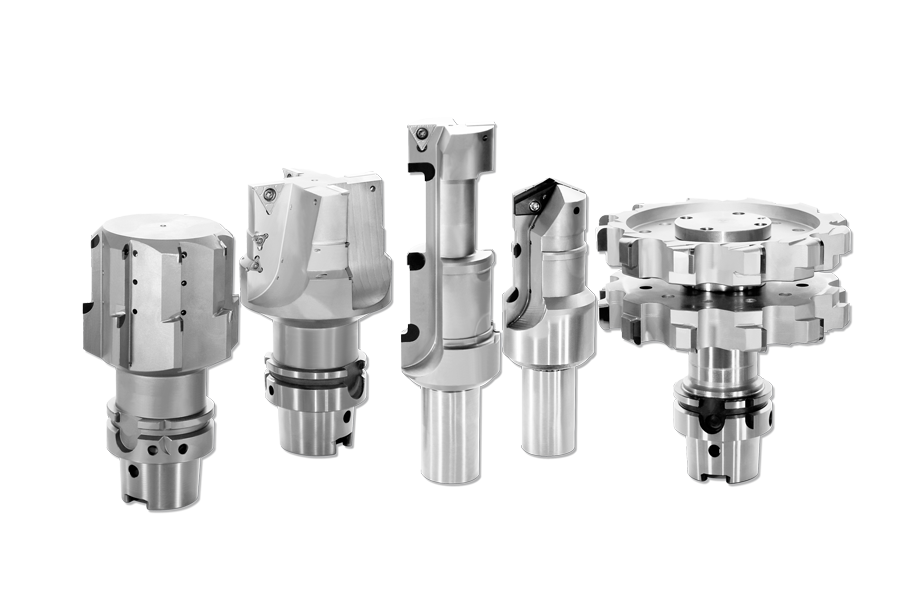

When we heard that the tool builder couldn’t offer a solution, we brought in one of our trusted vendor partners to develop a custom AXN rotary indexing chuck system. This new system combined roughing and finishing of all 6 tools into one, roughing the interior and exterior of tools at once. This change reduced cycle times down to 52 seconds, almost 3.5 times faster thanthe previous 3 minutes. The new system also involved a change in tooling, from carbide to a high quality Polycrystalline Diamond (PCD) for better wear resistance. We tested the solution in advance at the chuck manufacturer before implementing it live for the client. This approach allowed them to continue their production without the interruptions of testing a new process.

In the first year, the customer saw an initial net cost savings of approximately $400,000, with an average on-going savings of $300,000 year after year. In this case, we offered more than a quick fix to our client. We heard their challenges and provided and implemented solutions for overall process improvement, immediately upgrading cutting efficiency, while reducing the amount of tool changes and reducing cycle times.